A typical distribution center or warehouse is responsible for receiving goods from various suppliers and delivering them to specific terminals or storing them for future shipment. There is immense pressure to improve productivity and reduce labor costs in these operations. To achieve this goal, one approach that distribution centers can adopt is upgrading to digital code reader technology that offers higher read rates.

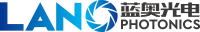

Vision systems provide solutions for many logistics applications. For instance, an automated sorting system can enhance inventory management by integrating computer software and POMEAS machine vision technology to track and move goods within a factory. It requires fast and continuous or simultaneous reading of 1D and 2D barcodes on all sides of the packaging.

The logistics industry's vision system solutions include:

- High-resolution dual-sided telecentric lenses

- Industrial cameras with gigabit Ethernet interfaces

- Industrial computers equipped with an I5CPU and 4GB of memory

The logistics automated sorting operation is designed to meet various packaging classification requirements. Image-based code readers are crucial for decoding information and ensuring accurate packaging classification and delivery. Achieving high read rates at the automatic sorting position is vital for reducing labor costs and increasing processing capacity in barcode reading applications.

Keywords:

1. Digital code reader technology

2. Vision system

3. Automated sorting system

4. High read rates

5. Logistics operations