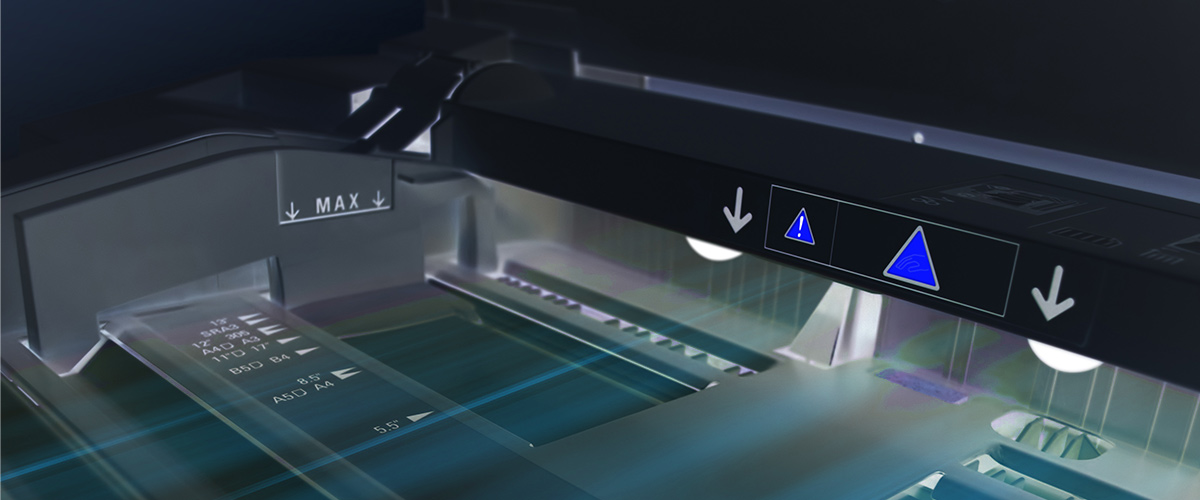

Machine vision technology is utilized on factory production lines to replace manual inspection, enabling real-time monitoring of product status. This helps prevent the shipment of defective products caused by factors such as human fatigue, while also reducing labor costs and improving production efficiency for manufacturing enterprises.

Currently, machine vision inspection is primarily applied in the field of online surface detection. Data acquisition is performed using machine vision image acquisition systems, and defect analysis and parameter storage are conducted using machine vision software.

In early 2018, in response to industrial customers' transition from single-dimensional to multi-dimensional functional requirements, Lanao introduced various functional industrial lenses. These lenses range in pixel resolution from 3 million to 20 million, capable of meeting diverse visual needs including object positioning, detection, recognition, and measurement.

Keywords: machine vision technology, real-time inspection, defective products, production efficiency, industrial lenses.